-40%

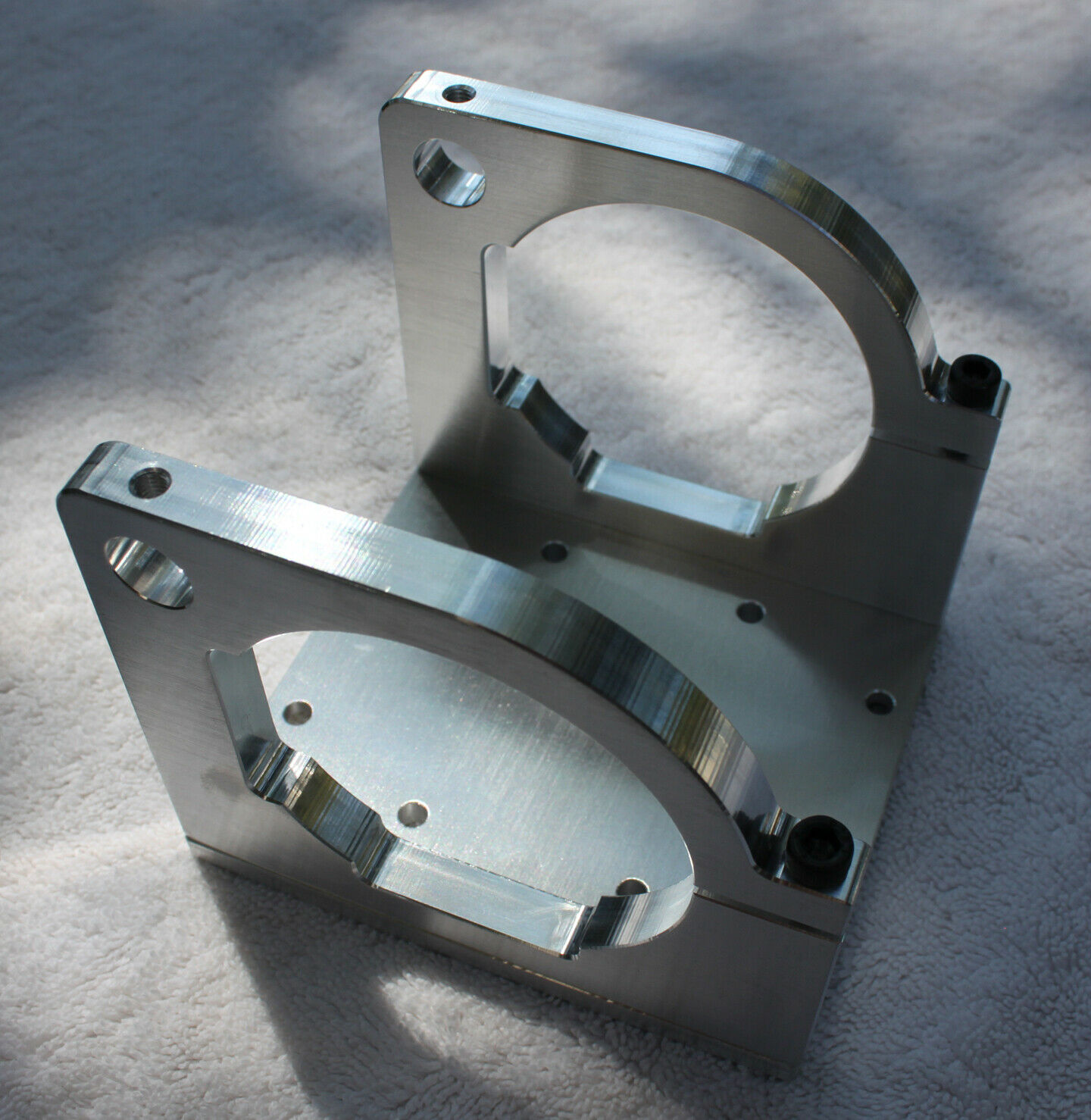

1PCS Corn Milling Cutter Carbide Circuit Board PCB Milling Cutter CNC Tool Head

$ 3.32

- Description

- Size Guide

Description

product descriptionProduct name: Corn milling cutter (lengthened)

Product material: overall tungsten steel

Whether the coating: no coating

Shank diameter: 4mm

Blade diameter: 4mm

Blade length: 12mm-52mm

Total length: 45mm-80mm

Knife speed: 3~5m/min recommended

Feed recommendation: 80%~100%

Parameter setting: 3000-5000

Suggested speed: 18000~20000 rpm

Applicable materials: circuit boards, bakelite boards, epoxy boards, gold, silver, copper, iron, aluminum and other metal processing.

Applicable machines: machine tools, advertising engraving machines, CNC machining centers, gong machines, etc.

Blade length selection: In addition to the specification limit, the blade length is 2~5mm longer than the plate, and too many blades are easy to break

Speed description: Some customers think that the slower the knife, the more difficult it is to break. In fact, the sharper the knife, the slower the knife, and it is easy to burn and break the blade.

main feature

Using mirror sharpening technology, large-capacity chip flutes, sharp edge, wear-resistant, smooth and delicate cutting surface, non-polished, non-stick pan, smokeless and tasteless, silent

Tool selection

In order to achieve the purpose you require, please try to use short-edged tools. Too long cutting edge or too long tool body will cause vibration and deflection during the machining process, which will damage the tool and affect the machining quality. We recommend using a tool with a larger shank diameter.

Tool operation

(1) Woodworking milling cutters are specially designed for portable and desktop woodworking engraving machines. They cannot be used for electric drills and drilling machines.

Flight.

(2) The tool can process smooth surfaces on hardwood, softwood, synthetic boards and other wood, but avoid processing

Metal materials such as copper and iron and non-wood materials such as sand and stone.

(3). Be sure to use a jacket of the right size, which is severely worn, not round enough, and the inner hole has a taper.

Failure to provide sufficient clamping force will cause the tool handle to vibrate or twist and fly away.

(4) Don't think that the new jacket must be safe and reliable. When clamping the tool, it was found that the tool holder was not evenly connected.

When there are traces or grooves, it means that the inner hole of the jacket has slipped and deformed. At this time, the jacket should be changed immediately.

So as to avoid accidents.

(5) After the tool is clamped, if the tool is found to bounce while working, it should stop immediately and re-clamp

Before continuing, let the tool handle and the sheath come into full contact a few times.

(6). The handle of the tool should be in good contact with the jacket. The tool handle must be fully inserted into the sheath and tightened.

So as to provide sufficient clamping force for the tool. Only a small part cannot be inserted into the jacket, otherwise it is easy to manufacture

The tool handle is broken and the tool is damaged.

(7) Use appropriate eye and ear protection devices during operation.

(8) Keep your body, clothes and other sundries away from the tool during work

Tool maintenance

(1) Keep tools clean, remove resin, sawdust and other dirt on wood, use standard workers

Industrial solvent cleaning tools.

(2) Apply a small amount of oil to prevent surface corrosion, and wipe all the stains on the handle of the tool to prevent sliding during processing.

(3) Do not repeat the tool and the shape of the tool without authorization, because each grinding process requires professional grinding equipment and professional grinding technology, otherwise it is easy to cause cutting fractures and cause accidents.

If you need other quantity, please contact me, the more quantity, the greater the discount!