-40%

Barker AM Horizontal Milling Machine W/ Heavy Duty Cabinet & 5C Collet Fixture!!

$ 1458.6

- Description

- Size Guide

Description

Important Bidding /Buying Information Related To This Listing;We Have Done Our Best To Describe It In Detail ;However, This Is A Used Item And In Our Opinion A Good One ;However, Opinions Can & Will Differ On Occasion And Because Of This We Ask That You Be 100% Sure You Know What Your Buying & What To Expect When It Arrives

Even Though The Machine Looks Good It Is Used So We Prefer And/Or Strongly Recommend You Visit & Inspect It Yourself In Person ;However,Should This Not Be Possible Or Practical Please Review The Photos & Ask As Many Questions As Possible So You Know What To Expect When It Arrives !!!

Notice ;

This Has Been ,Inspected And Tested For It's Function Only ...We Can Not & Do Not Determine If It Meets Any And/Or All Safety Issues And/Or Concerns With Regards To The Machine, It's Installation ,Operation & Safe Guarding.

Any And/Or All Issues Or Concerns With Regards Safety Are The Buyers Sole Responsibility And By Purchasing This Machine You Are Agreeing And Accepting The Terms Above

Machine Details & Specifications

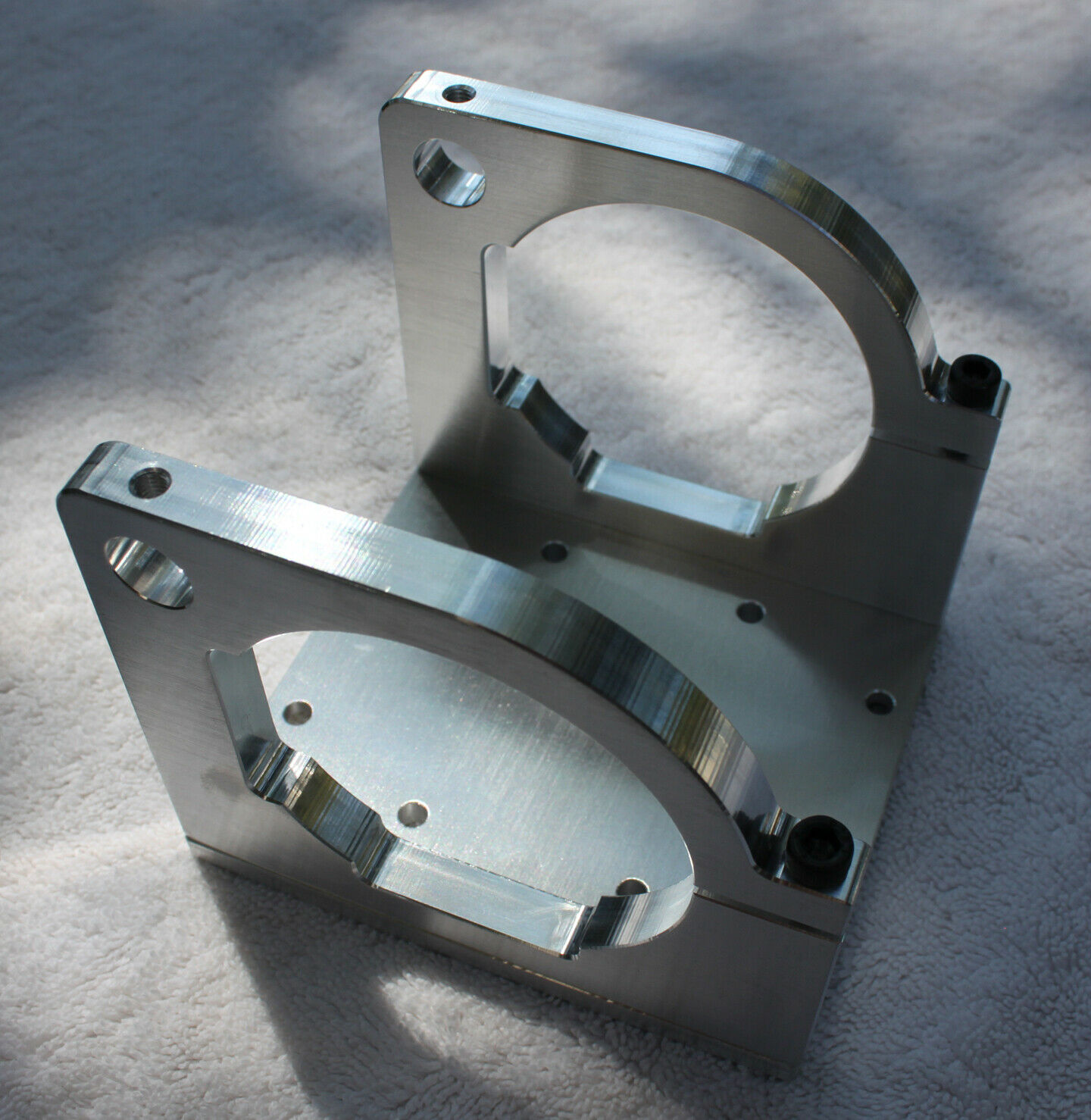

(1) Pre-Owned/Used Barker AM Horizontal Milling Machine W/ 5C Collet Fixture

AM General Specifications

Table:

Standard working surface 6-1/4" x 20" with 10" maximum longitudinal travel

Saddle:

Cross travel 4" maximum

Head:

Vertical travel 6" maximum W/ riser block +4"

Spindle:

No. 30 Milling Machine Taper

Motor:

220/440/60/3 - T.E.F.C. - 2 HP

Standard speed 1725 RPM

Color:

Machine Tool Gray

Approximate

Shipping

Wt:

775 lbs. (machine with cabinet base)

Belt Change Spindle Speeds W 1725 Rpm Motor

55 Speed 530,715,940,1200& 1530 Rpm

Standard Equipment For AM

Hand lever feeds to head, saddle and table motion with adjustable positive stops

Motor: 2 HP, 1725 RPM, 3 phase, heavy-duty, ball-bearing, totally enclosed, fan-cooled, dual voltage

Forward/reverse drum switch

Belt guard

Phase II Universal 5C Collet Fixture

The AM milling machine is designed and built for high quality, high production and high precision machining operations.

All machine sliding surfaces are hand scraped and accurately aligned to meet today's high standards for

close

tolerance machining.

The spindle is hardened and precision ground with a No. 30 milling machine taper, mounted on precision Timken Bearings.

Mill clearances will accommodate most indexing heads, vices and other holding fixtures

This Runs Great And It Still Has Most Of The Original Hand Scraping Marks So You Know It Hasn't Seen Much Use ...It's In Excellent Condition !

Important Safety Notice

...There are no safety devices or E-stops on this machine and there are no safe guards to protect the operator ,upgrades are required and should you purchase this your assuming the responsibility for any and all safety upgrades needed.

Buyer's Responsibility And Indemnity: It shall be Buyer's responsibility to ensure that any machinery and/ or tooling purchased from

Davis Machinery LLC

is installed and operated in a proper and safe manner. The Buyer also acknowledges that it may

have to install or change guards, safeties, warnings or other components to ensure that the machinery and/ or tooling purchased hereunder will conform to all laws, regulations, ordinances, codes, insurance requirements and industry standards,Including any and all

Safety Requirements & Standards

Packing /

Skidding

5.

Packing /Crating 5.

Please ask any and all questions as early as possible so we an answer in time for you to bid.

Sincerely ~

Brenda & Cliff Davis

Davis Machinery LLC

4012259582

bdavis AT davismachinery DOT c o m