-40%

Custom Parker 404XR CNC Precision Linear Actuator w/ Ballscrew Mach3 GeckoDrive

$ 3036

- Description

- Size Guide

Description

Item Specifics:Custom Built Parker 404XR CNC Machine

GeckoDrive G201 Stepper Controller

Includes Computer +

Mach3 Software

X Travel = 400mm (415mm max)

Y Travel = 300mm (310mm max)

Z Travel = 100mm (120mm max)

16mm dia Precision Ground Ballscrew

s

Proximity Sensors (Limit Switches)

Includes all cables and is ready to Plug-N-Play

I have run a test program on this machine and

posted a video to YouTube:

https://www.youtube.com/watch?v=bTLtO4cTvM4

https://www.youtube.com/watch?v=bTLtO4cTvM4

---------------HIGH VOLTAGE WARNING !!!----------------

THIS MACHINE HAS HIGH VOLTAGE COMPONENTS

.

THE CONTROLLER CASE WAS BUILT WITH ALUMINUM

FRAMING AND IS NOT 'UL APPROVED' AND IT IS

POSSIBLE THAT IT MAY NOT BE GROUNDED PROPERLY.

IF YOU DO NOT HAVE THE EXPERIENCE TO WORK

WITH HIGH VOLTAGE ELECTRICAL EQUIPMENT,

THEN PLEASE

DO NOT

BUY THIS CNC MACHINE.

I AM NOT LIABLE FOR ANY ACCIDENTS RESULTING

FROM THE IMPROPER USE OF THIS EQUIPMENT.

THIS INCLUDES PROPERTY DAMAGE, BODILY INJURY OR LOSS OF LIFE.

Item Description:

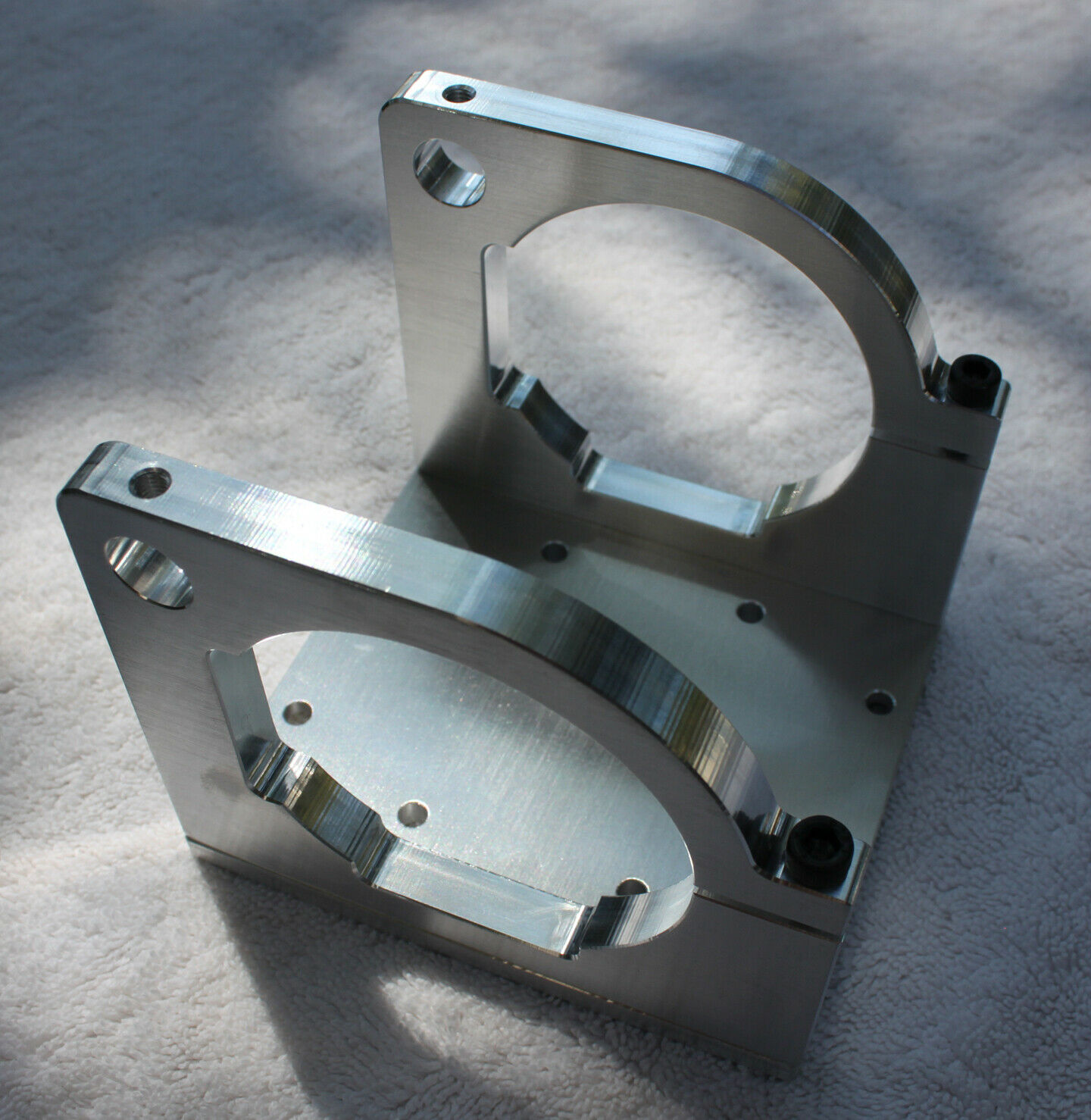

This is a custom Parker 404XR CNC machine that was built a

few years ago but never put into service. It only has a few hours

of run time for testing but it has never had a spindle attached to it.

It was built using mostly new parts (the three longer 404XR actuators

were lightly used but are in excellent working condition). This is a

complete turn-key system that includes computer with Mach3

installed

and is ready to plug-n-play.

See YouTube video for demonstration.

It is a 3-axis machine with with dual Parker 404XR actuators on

the 'Y' axis (the 'Y' and 'A' axis are slaved together and the controller

uses a 4-axis Mach3 breakout Board). The 'Y' and 'X' axis actuators

have new Parker nema34 stepper motors and the 'Z' axis has a new

Pacific Scientific nema23 stepper motor. All of the Parker 404XR

actuators have 16mm diameter precision ground ballscrews, and

all actuators also have proximity sensor (limit switches) that are

wired to the breakout board to prevent overtravel. The controller

uses a 4-axis SoundLogic breakout board and GeckoDrive G201

stepper drivers with an Antek 39v 500watt unregulated power supply.

The front of the controller has a 'Power On' and 'Stop' button that

turn the machine on/off. The 'Emergency Stop' button on the controller

will send a signal to the Mach3 breakout board to stop a program that

is running and will stop the machine from moving but will not cut power.

There is a digital voltage meter and amp meter the measures the output

of the Antek power supply. The four 'On / Off' switches are used to disable

the G201 drives and cut power to the stepper motor so that you can

manually adjust the axes if needed. The 'Y&A Axis Lock / Unlock' switch

is used in conjunction with the 'On/Off' switches and when the Y and A

axis are 'locked' you only need to turn off one of the switches (Y or A) and

it will disable both motors on the Y/A axis so that the Y axis can be

manually adjusted. If you only need to adjust one motor at a time you

can 'Unlock' the Y and A axis and that will give you independent control

of the Y and A motors using the 'On/Off' switches. (Please note that there

is a timing belt at the rear of the machine that is used to keep the Y and A

axis synchronized, so to adjust the motors independently you would need

to loosen one of the pulleys). There are also digital temp gauges below

each 'On/Off' switch that measure the temperature of the GeckoDrive

G201 stepper drives (the temp probe is attached to the G201 heatsinks).

The machine has never had a spindle attached to it but it does have

a 'Spindle Out' 120v plug at the rear of the controller that is software

controlled using the M3 & M5 command in Mach3 (M3 = On , M5 = off).

There is also an extension cord that has already been run from the

back of the controller to the Z-axis actuator (you can see the orange

120v plug at the top of the z-axis), so all you have to do is mount a

120v spindle to the z-axis and plug it into the extension cord.

There are two 120v power inputs on the back of the controller, the

'Main - In' is what supplies power to the machine and the 'Aux- In'

only supplies power to the 'Spindle - Out' (the 'spindle out' socket

is controlled using a 25amp solid-state relay controlled with Mach3).

The computer that comes with this machine is a newly refurbished

Windows XP computer that I purchased on Ebay and the only thing

I have done to it is install a licensed copy of Mach3 software on it.

The machine and controller were built using 2040 (2" x 4") aluminum

framing that was purchased from 80/20 net. The computer stand

is something that I bought separately and I believe it is constructed

using Bosch/Rexroth 30mm square aluminum framing. The stand

has locking casters on it so that it can be moved around easily.

Specifications:

Dimensions (width/depth/height):

Computer stand = 25"w x 25"d x 30-1/2"h

Controller = 28"w x 24"d x 4"h

CNC Machine (Main Frame) = 30"w x 22"d x 16"h

Machine Travel:

X Axis = 400mm rated travel (415mm max)

Y Axis = 300mm rated travel (310mm max)

Z Axis = 100mm rated travel (120mm max)

Machine Velocities:

X Axis = 450ipm

Y Axis = 400ipm

Z Axis = 150ipm

X-Axis Components:

Parker 404400XRMS-D4 Actuator (20mm pitch ballscrew)

Parker OEM 83-93-MO Nema34 Dual-Shaft Stepper

Y-Axis Components:

(x2) Parker 404300XRMS-D4 Actuator (20mm pitch ballscrew)

(x2) Parker OEM 83-93-MO Nema34 Dual-Shaft Stepper

Z-Axis Components:

Parker 404100XRMP-D2 Actuator (5mm pitch ballscrew)

Pac-Sci E22NCHT Nema23 Dual-Shaft Stepper

Controller:

(x4) GeckoDrive G201 7-amp Stepper drives

SoundLogic 4-Axis Breakout Board

Antek 39v 500Watt Power Supply

(x4) 120v Cooling Fans (x2 Intake , x2 Exhaust)

Computer

:

HP Compaq Desktop Tower

Intel Core 2 Duo 2.80ghz

4gb Memory

80gb Hard Drive

Windows XP Pro

with Licensed copy of Mach3

Dell 17" LCD Monitor

Parker 404XR Website Link:

parker.com/Literature/Electromechanical%20North%20America/CATALOGS-BROCHURES/XR%20Literature/404-406XR-Series-Linear-Positioners_Manual.pdf

Shipping Details:

Standard Shipping is not available

because this item is too heavy.

This is available for local pick-up.

Or the buyer can arrange a freight shipment.