-40%

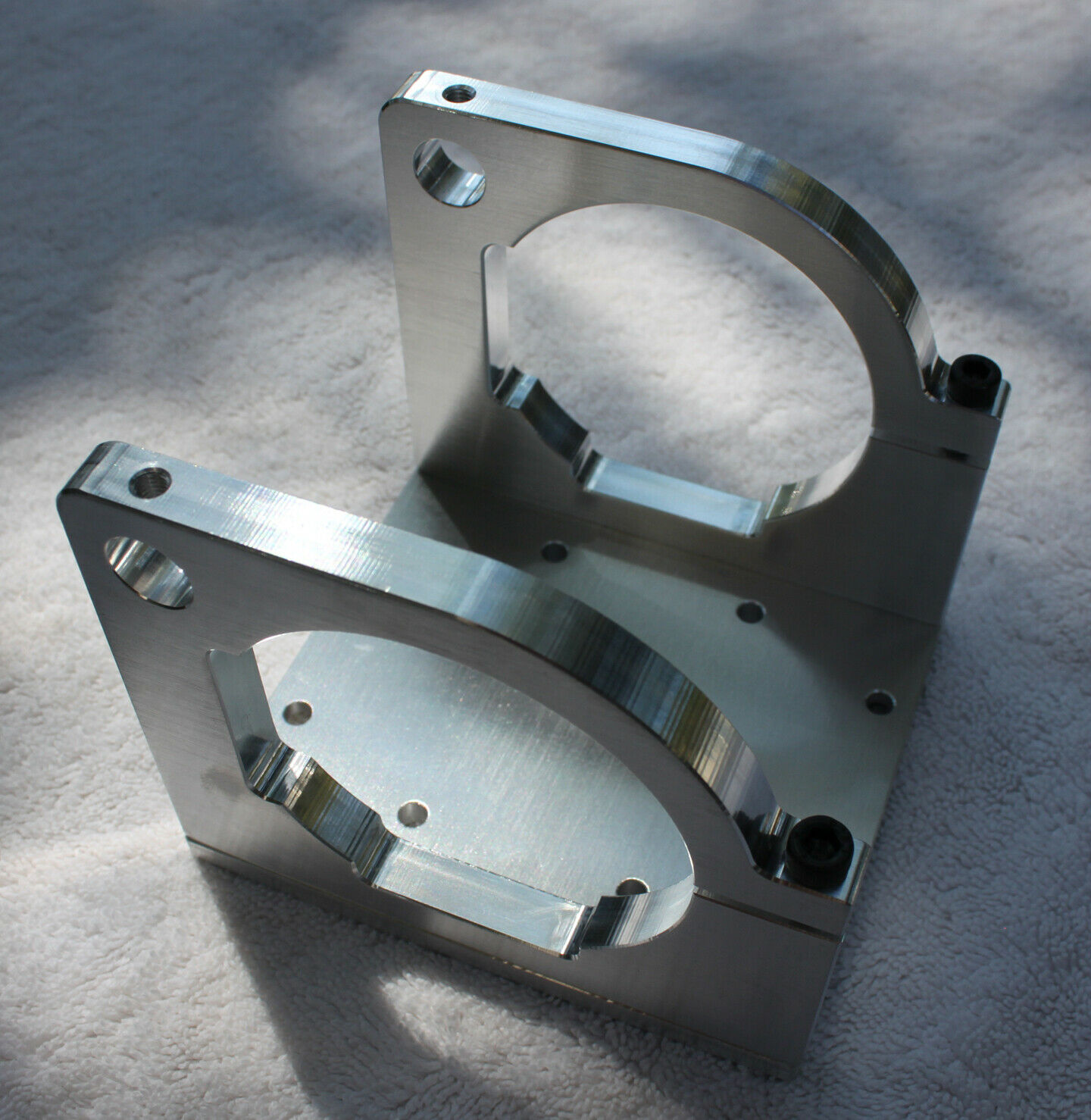

Rotary File M Type Metal Grinding Head Tungsten Steel Alloy Wear-resistant6-16mm

$ 3

- Description

- Size Guide

Description

product descriptionName: Tungsten Steel Rotary File

Handle diameter: 6mm

Diameter of cutter head: 6-16mm

Milling cutter type: M type

Tooth type: single slot/double slot

Material: Carbide

Features: high hardness, wear resistance, not easy to break.

Coating: Uncoated

Applicable equipment: pneumatic or electric drive tools

Use scenarios: such as parts processing, engraving, chamfering, rounding, grooves, etc., casting, forging, and grinding of weldments, etc.

Use scenarios: mold processing and manufacturing, mechanical chamfering, rounding and bevel processing, casting, forging, welding flash, burr and weld cleaning, metal and non-metal material technology, etc.

Tool use: Tungsten carbide rotary file (tungsten steel grinding head) has a wide range of uses. Used for mold processing and manufacturing, chamfering, rounding and beveling of mechanical parts, removing flash, burr and burr of casting, forging and welding parts. Metal and non-metallic materials (bone, jade, stone, etc.) welds, pipes, impeller flow channel finishing, arts and crafts sculptures.

Instructions for use:

Carbide rotary file (tungsten steel grinding head) is mainly used for electric tools or pneumatic tools (can also be installed on machine tools). The matching drive speed is generally 6000-50000 rpm.

The difference between double slot and single slot:

Because the double flute is a cross pattern, it is more suitable for objects with lower density. For example: suitable for wood, plastic, aluminum, etc.! The cross pattern chip removal speed is fast, and it is not easy to block the pattern when grinding and engraving, so double grooves on soft objects are more suitable!

The single-slot pattern determines that the use of softer objects is not ideal, because when a single-slot knife cuts, debris can easily block the groove, resulting in shallower grooves and reduced cutting volume; that is what we usually call the knife is not fast! Single slot is more suitable for hard objects such as iron, copper and steel.

<

➊Mainly used for pneumatic or electric tools;

❷ The speed is generally 6000-50000 revolutions;

❸Clamp the tool to the correct position when using it, and the cutting method should be up-cut milling to avoid reciprocating cutting;

❹In order to prevent chips from flying out during work, please wear protective glasses.

Packing description: plastic bag/carton

If you need other quantity, please contact me, the more quantity, the greater the discount!